- Overview

- Delivery

- Preliminary treatment

- Digestion

- Biogas processing

- Treatment of ferment residues

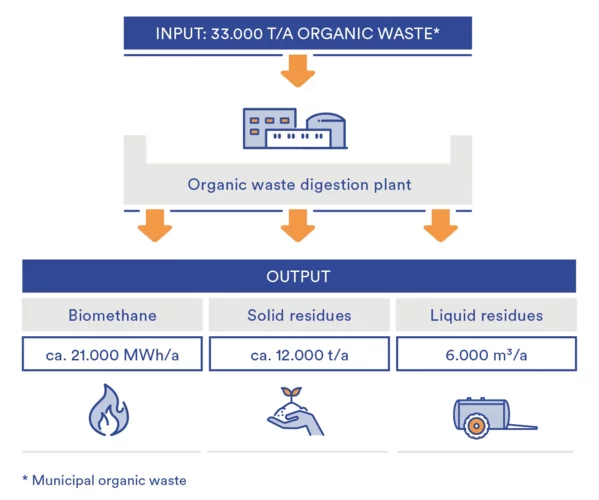

- Input and Output

We use municipal biowaste to generate biogas

Clean energy from biowaste

Potato peelings, garden leaves, food leftovers – everything we put in the organic waste bin can be turned into green energy in future. Working with state-of-the-art biowaste anaerobic digestion plants, we convert this waste into environmentally friendly biomethane. This can be used to generate electricity, and heat, in the transport sector and in industrial processes. The residues remaining once the waste has been digested can be reused as valuable compost in gardens and in agriculture. Unlike traditional biowaste composting, biogas generation uses the energy stored in the waste and reduces emissions of methane and carbon dioxide.

Our plant in Dresden-Klotzsche processes around 46,500 tonnes of biowaste a year. We are currently building a further plant with a capacity of around 33,000 tonnes a year in Bernburg/Saale in Saxony-Anhalt, and we are planning further biowaste anaerobic digestion projects across the whole of Germany.